Part 2: Modified Bitumen

Polymer-modified bitumen roofing is a subset of asphalt roofing. Before these roofing sheets are formed, asphalt is heavily modified with APP or SBS rubber. These two technologies provide products with significantly different properties. SBS materials can be installed in moppings of hot asphalt, with cold adhesive or torch-applied. They may be used as hybrid systems and typically are finished with a mineral-surfaced cap sheet. A thick APP base sheet often is used with granulated SBS sheet on top, and, in most parts of the U.S., it is torch-applied rather than adhered with hot asphalt or adhesives. APP most commonly is available as a smooth-surfaced material though granule surfaces also are available.

Recently, some manufacturers have introduced white polymer-modified bitumen cap sheets that may be used to cap traditional BUR systems. If they provide reflectance values above 0.70, the roof systems qualify for an exemption from California's Title 24.

Various protective and reflective coatings also can be applied to polymer-modified bitumen substrates in the field.

Much of what applies to BUR systems also applies to polymer-modified bitumen roof systems. Polymer-modified bitumen roof systems generally are compatible with coatings developed for conventional BUR systems; aluminum and white coatings commonly are used. Elastomeric acrylic coatings can be applied to smooth polymer-modified bitumen and mineral-surfaced cap sheets to turn their black surfaces white and extend roof system life cycles while lowering energy costs.

Elastomeric acrylic coatings featuring non-bleed formulas recently were introduced. These coatings provide asphaltic substrates with a cool, bright white, protective seal. These specially formulated coatings maintain their bright white surfaces for long-term performance.

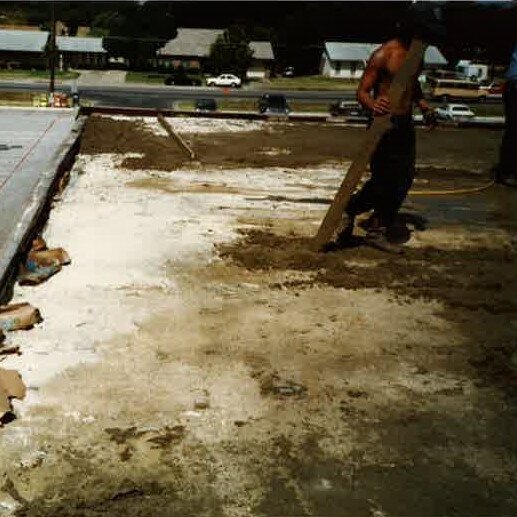

Roof systems with asphaltic substrates must be aged at least 90 days before white elastomeric acrylic coatings can be applied. If a substrate previously was coated with an unknown coating, an adhesion test must be performed. After a successful adhesion test, all loose existing coatings and debris must be removed and the roof surface power washed with water. Excessively soiled or greasy surfaces—common on smooth APP—may require additional cleaning with a stiff-bristle broom or scrub brush.

Mineral-surfaced cap sheets are perhaps the easiest to coat in the field. These surfaces are rough enough to provide excellent adhesion but not so rough as to require a large volume of coating material. Mineral-surfaced cap sheets have a surface roughness of 30 to 50 mils. An initial coating of 10 mils with asphalt emulsion tends to fill in the voids and serve as a good substrate for a white coating.

A smooth polymer-modified bitumen roof system also can be coated with an asphalt emulsion coating and topped with a compatible white acrylic coating depending on the target reflectivity value.

Source: Professional Roofing